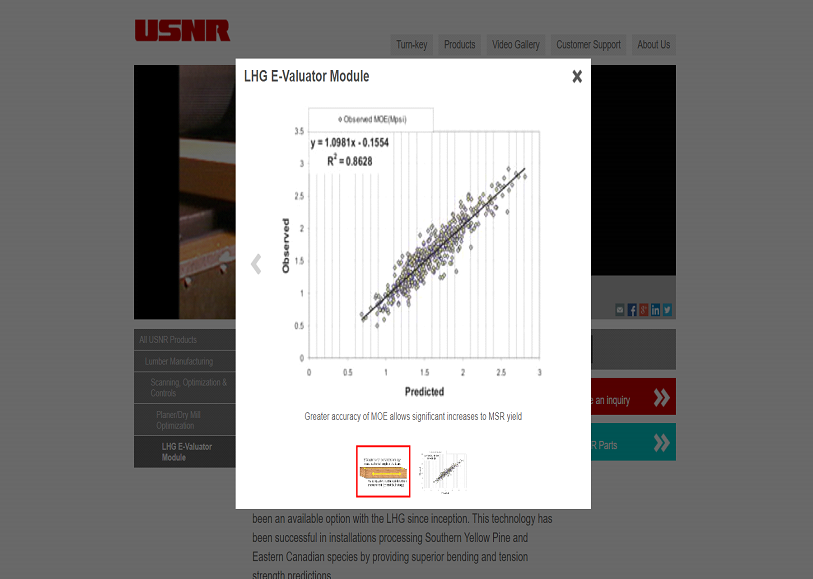

The Lineal High Grader (LHG) E-Valuator Module provides non-contact measurement of Modulus of Elasticity (MOE). Greater accuracy of MOE allows significant increases to MSR yield. E-Valuator predicts the strength of the board by measuring the frequency at which the board vibrates as it travels though the scanner frame, combined with density measurements provided by x-ray technology.

X-ray density measurement for prediction of MSR/MEL-rated lumber has been an available option with the LHG since inception. This technology has been successful in installations processing Southern Yellow Pine and Eastern Canadian species by providing superior bending and tension strength predictions.

Early on it was recognized that lumber passing through the scanner feed rolls exhibited vibration that can be measured. Further, the vibration measured by the scanner represented the natural frequency of a board corresponding to its MOE.

E-Valuator software utilizes this frequency measurement. Board vertical displacement is measured with the laser profile (LPR) subsystem, also used for wane and other geometry characteristics.

The key to E-Valuator's success is highly accurate measurement of the board's vibration profile with our custom noise reduction algorithm. It permits even very small amplitude signals to contain useful vibration information.

The board's vibration profile is then combined with its density profile (from x-ray measurements) and feed speed. A mathematical equation calculates its vibration MOE. E-Valuator technology does not replace the strength prediction of the XLG module, but combines with it to provide a comprehensive MSR solution. Unlike other MSR machines, LHG’s E-Valuator module predicts MOE, bending, tension, moisture, slope of grain, and knot size with location, providing the complete and accurate data required to control your strength graded products.

Unlike Other MSR Machines:

⦁ LHG's E-Valuator module predicts Modulus of Elasticity (MOE), bending, tension, moisture, slope of grain,

and knot size with location. E-Valuator provides the complete and accurate data required to control your

strength graded products.

Automated Grading with MSR, One Machine:

⦁ E-Valuator is field proven since 2006 to outperform HCLT systems in bin yield for western SPF.

⦁ E-Valuator increases the value of the recovered product by correctly classifying a greater percentage of higher grade MSR in the mix.

⦁ Non-contact x-ray and vibration measurement means no board deflection, resulting in less board breakage and permitting higher planer feed speeds and high up-time. It also means no special calibration is required, beyond standard X-ray cal-check performed automatically. Less mechanical contact leads to less chance of wear, fatigue, and other types of mechanical issues.

⦁ E-Valuator is completely integrated into the LHG system. It requires only laser profile and x-ray subsystems.

⦁ An optional vision subsystem provides additional board information such as knot size and location, slope of grain, rate of growth, checks and shakes.

Features and Benefits:

⦁ All-in-one solution for visual, MSR grading and optimization.

⦁ Non-contact measurement for easier maintenance, greater uptime.

⦁ End-to-end measurements - no limitations.

⦁ Complete serial moisture integration.

⦁ MSR edge knot control.

⦁ Cut-n-two and trim back optimization.

⦁ Slope of grain, rate of growth, check and shake control.

⦁ Easily upgradeable - additional sensors fit within existing frame.

⦁ Approved by ALSC (American Lumber Standards Committee).

⦁ Direct measure of density and vibration for exceptional strength and stiffness determination.