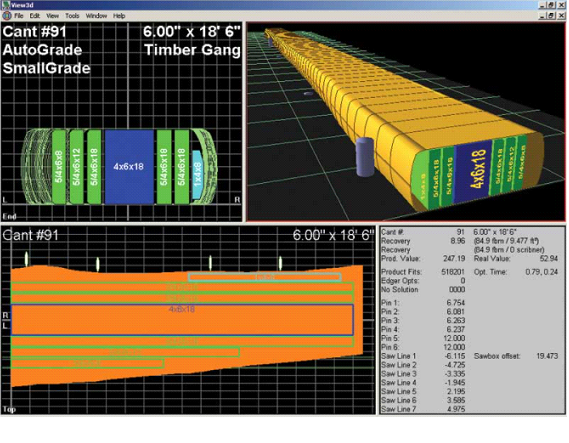

The Cant Optimizer allows different products with different values,

targets and wane rules to be placed in specific areas of the cant.

The system also includes full support for curve sawing. Advanced

capabilities include surface feature recognition which allows cant

characteristics such as diameter, length, taper, sweep, and surface

roughness to classify user definable grades. Multiple, concentric

grade zones can then be easily configured within the cant allowing

different products with different values, targets, and wane rules to

be placed in specific areas of the cant.

Maximum Value from Every Cant

Combining dense 3D scan data with the power of today’s highspeed

computers, the WoodExpert Cant Optimizer System lets you get the

maximum value from every cant. The complete solution includes

scanning, optimization and information management along with full

support for curve sawing.

Advanced capabilities include surface feature recognition which

allows cant characteristics such as diameter, length, taper, sweep,

and surface roughness to classify user definable grades. Multiple,

concentric grade zones can then be easily configured within the cant

allowing different products with different values, targets, and wane

rules to be placed in specific areas of the cant.

Configurable to Model Machinery

⦁ All saw, chipper, clamp, and pin characteristics.

⦁ Gang saw spacing, including fixed or variable board spacing.

⦁ All common curve sawing machine centers (both mechanically guided

and numerically-controlled).

⦁ Machine centers with left or right linebars and cant rotation.

⦁ Cant positioning methods including lineal and transverse.

⦁ Lineal and transverse.

Detailed Product Description Entry Windows

⦁ Offers unlimited number of products with up to 16 lengths per

product.

⦁ 4, 5, 6 and 8-point wane models, including secondary wane, with

graphical representation of each product.

⦁ Quick cutplan change and board product activation.

⦁ Assignable bin destinations for each product.

System Fine-Tuning Includes parameters to specify:

⦁ Up to 12 skew orientations for the optimizer to consider.

⦁ Up to 12 curves for the optimizer to consider.

⦁ 1-7 order polynomial sawlines for the optimizer to fit for curve

sawing solutions.

⦁ Programmable radius of curvature for various cant diameters.

⦁ Vertical shifting of solutions.

⦁ Opening face requirements.

⦁ Configurable edging and planing penalties.

⦁ Chip limits.

⦁ Risk analysis.

Re-optimization Features Off-Line Analysis

⦁ 3-D cant images can be automatically saved to files for later

off-line re-optimization.

⦁ Re-optimizes hundreds of recorded cant images in minutes.

⦁ Off-line and on-line results are identical, allowing for

fine-tuning of settings without risking real wood.

System Architecture

⦁ Microsoft Windows Professional multithreaded, multi-tasking,

preemptive operating system, supporting multiple processors on an

Ethernet local area network (LAN).

⦁ Most common PLCs supported.

⦁ Configurable Business Objects reporting package.

Complete Suite of Reports

⦁ Provides complete information on system production and

performance, for accurate management decision-making.

Export Reports

⦁ Export reports to other formats like spreadsheets, databases, word

processors, and e-mail. Allows you to easily share information with

colleagues and re-purpose information for statistical purposes.

Reports on Demand

⦁ Print reports on demand or automatically to a preset schedule.

Information is available when you need it.

Create Your Own Custom Reports

⦁ Custom-design reports as needed for your mill’s individual needs.

Uses industry standard Business Objects reporting software and dBase

IV databases.

User Assistance

⦁ Technical support by telephone and e-mail along with remote

debugging by modem or broadband internet.