With unparalleled accuracy and simultaneous front and back side

scanning, it’s the only system capable of full log breakdown grade

sawing that can also be configured for hardwood MOF applications.

This full coverage 3D scanning sensor has unparalleled resolution

and data density providing more accurate log volumes, and better

monitoring of yield and overall mill performance.

High Density 3D Scanning

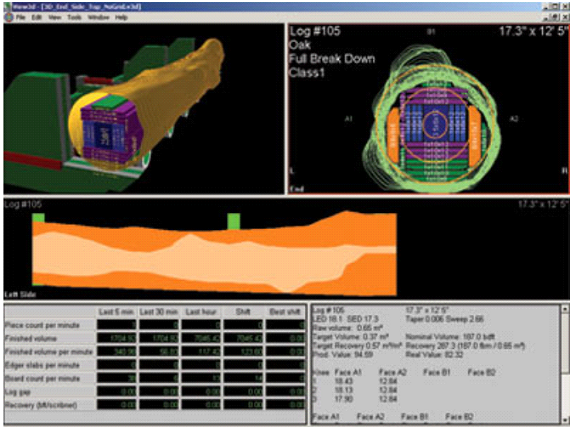

The LASIOR sensor-based WoodExpert Carriage Optimizer combines dense

3D scan data with the power of today’s high-speed computers to let

you get the maximum value from every log.

The system's

simultaneous front and back side scanning offers unparalleled

accuracy and data density. It’s the only system capable of full log

breakdown grade sawing and can also be configured for MOF (minimum

opening face) in hardwood applications.

The system provides

detailed breakdown rules that can be set for each species, grade and

fiber class along with other options including configurable face cut

orders, configurable minimum opening face sizes and lengths, half

taper, full taper, and no taper options.

Sees the Whole Log

⦁ Up to 300 degrees of log coverage, front and back, with a dense

data blanket, not sparse scan lines (tens of thousands of data

points from the backside alone).

Scans Full 3D Image

⦁ Scans full 3D image of the entire stem in one place, even very

crooked and swept stems.

⦁ Log lengths detected to ½” - no need to move the carriage to get

the log length.

High Accuracy LASIOR Sensor System

⦁ Log diameters within 0.125” with single point resolution of

0.036”.

Multiple, Adjustable Scan Zones / Stop-N-Loader Scan Zones

⦁ Small, medium, and large scan zones ensure maximum coverage area

and maximum scan density on every size log.

⦁ Stop-n-loader feature allows pre-positioning of the carriage knees

to accept the next log, pre-loaded close to the saw line, for faster

throughput.