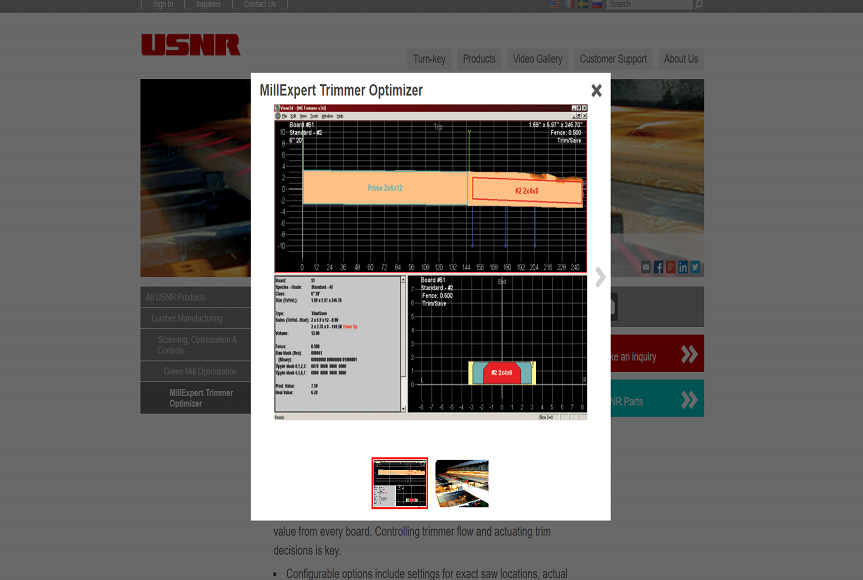

The WoodExpert Trimmer Optimizer system gives you control over how your boards are trimmed and handled. A wide array of features lets you configure and customize your system for maximum recovery, superior board control and ease of use. Configurable options include settings for exact saw locations, actual trim lengths, optimizer minimum product length allowed, compound wane rules, planer mill trimmer limit switch locations and cosmetic trimming, to name a few. The WoodExpert Trimmer Optimizer is compatible with our BioVision green mill grading solution.

Maximum Value from Every Board:

⦁ Combining dense 3D scan data with the power of today’s highspeed computers, the WoodExpert Trimmer Optimizer

lets you get the maximum value from every board. Controlling trimmer flow and actuating trim decisions is key.

⦁ Configurable options include settings for exact saw locations, actual trim lengths, optimizer minimum

product length allowed, compound wane rules, planer mill trimmer limit switch locations and cosmetic trimming,

to name a few.

⦁ High-performance sensors provide unparalleled data density and accuracy, collecting full coverage scans with

essentially no gaps in the data. Auto calibration, dynamic tuning, and sophisticated diagnostics are all part

of this complete solution.

Detailed wane definitions:

⦁ Allows precise conformance to corporate or industry grading standards – for example, SPIB, NGR, or NLGA.

⦁ Four and six point wane modeling.

⦁ Wane can be defined as percentage of wane or percentage of “good wood.”

⦁ Primary and secondary wane rules or equivalent wane rules.

⦁ Sophisticated compound wane rules and saddle wane (dip) fully supported.

Board Control Features:

⦁ Visible wane or board-in-board wane – configurable by board product – allows handling products to be planed and sold rough.

⦁ Flexible control over grade hierarchies allows precise definition of complicated relationships between grades, allowing better value out of each board.

⦁ Full support for random width and random length products.

⦁ Extra parameters control requirements for board ends – Includes precision end trim (cut-to-length). Allows cosmetic control over board appearance for more appealing lumber packages.

⦁ Fully optimized cut in two decisions – Longer pieces can be sent to the planer allowing decisions about the most valuable length for a board to be made as far downstream as possible.

⦁ Able to define trim block by-products, with precise control over trim block sizes/placement – Allows fitting of specialty recovery products, such as industrial shorts, finger-joint stock, or dunnage. These products are considered for fitting during the optimization, maximizing the value of each board.

⦁ Rip logic support – Supports side-by-side compound board fitting for reman or export products.

⦁ Supports multiple grade zones in each board – Optimizer decisions take into account high-precision dimensional grade information from various sources including scan data, operator input, and graders’ marks through an automatic grade reader and other external systems like stress rating machines, the PLC, and the operator’s console.

⦁ Fully customizable – Lets you work with the software in a way that reflects your mill, renaming items in the user interface to match your mill’s terminology, and display lists of products on-screen sorted the way you expect them.

⦁ Precise control over fence positioning – Controls travel toward and away from the saws, specifies fence travel increments, limitations on fence movements for reduced mechanical wear.

Software Features:

⦁ Real-time software features – Real-time variation reporting and troubleshooting tools monitor product mix, product tolerances and upstream machine accuracy to help discover and correct problems at an early stage.

⦁ Off-line simulation and test modes – Includes recorded board image and grade defect information for fine-tuning results and solving setup problems. Test mode useful for system diagnosis and evaluation. Allows capture of all pertinent info for non-destruct testing.

⦁ A complete suite of reports included with the system with customizable capability.

Machine Control Features:

⦁ Detailed machine parameters describe the mill’s equipment and capabilities to the optimizers. The software takes your machine’s exact capabilities – including exact saw positions, into account when determining the most valuable trim solutions, ensuring each board receives the optimum machine sets.

⦁ Supports a variety of saw configurations such as moving saws, flying saws and PET saws.

⦁ Controls travel toward and away from the saws, specifies fence travel increments, limitations on fence movements for reduced mechanical wear.

⦁ Minimum Conveyable Length parameter controls how short a piece may be that passes through the trimmer, and automatically insures feeding problems on the way to the sorter caused by too-short pieces are avoided.

⦁ Complex tipple controls fully configurable to tipple out specific products or types of products.

Scanner Features:

⦁ Very dense full-board scanning with no gaps in the data, vertically and horizontally. Our superior scan data density provides more detailed information about each board, allowing accurate lengths, accurate wane detection, accurate board sizes, and better detection of dimensional defects and warp.

⦁ Auto-calibrate function for fast tuning and easy routine maintenance.

⦁ Lengths accurate to better than 1/4 inch, with no extra photocell. Fewer components required for accurate board length detection decreases maintenance requirements and lowers cost of ownership.

⦁ Automatic failed sensor detection and automatic debris detection. Immediate on-screen notification alerts the operator to a problem with the system. Helps ensure maintenance issues are dealt with promptly.