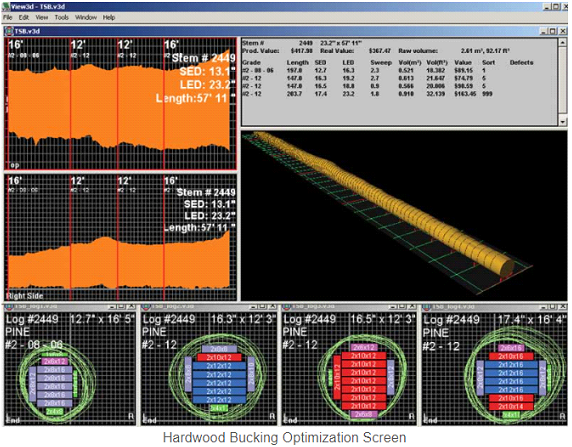

Full 3D modeling and optimization capabilities let you capture the

maximum value from every stem. With more features and functionality

than any other system, our Bucking Optimizer is fully customizable

to fit your exact needs. This system completely models downstream

machine centers, capability to remove waste pieces from middle of

the stem, fixed pattern breakdown, configurable routing codes for

log sorts, and much more.

Increased Grade, Recovery and Value

With more features, capabilities and scanning options than any other

system in the industry, our Bucking Optimizer combines dense 3D scan

data with the power of today’s high-speed computers to let you get

the maximum value from every stem.

Configurable to Model Machinery

⦁ Completely models the downstream machine centers (including

whether curve sawing is available).

⦁ Models whether bucking saws can remove waste pieces from the

middle of the stem.

⦁ Models fixed pattern breakdown.

⦁ Configurable routing codes to run log sorter.

⦁ Full support for metal detectors.

Operation can be Fined Tuned

⦁ User-selectable method of evaluating log diameters within the

stem.

⦁ Configurable maximum time allowed for optimization.

⦁ Configurable longest and shortest log lengths that may be cut.

⦁ Product value evaluation methods are sawlog “full fit”, volume,

veneer, sawlog pattern, variable length, JAS standard and price per

piece.

Detailed Product Description Entry

⦁ MillManager product setup screen allows complete detailed

descriptions of log products including the allowable ranges of small

and large end diameters, taper, and sweep.

⦁ Sweep too small to consider.

⦁ Sweep so extreme that value considerations are overridden.

Pattern Optimization Features

⦁ Board products can be associated with log products so that certain

boards are cut only from certain log grades.

⦁ Configurable bin destination for each log product.

⦁ Detailed log product grading capability: by density, eccentricity,

wobble, nodal swelling, catface, fluting, kink, machine damage,

resin pockets, scars, rot sap stain, and more, including detailed

knot grading.

⦁ Veneer product descriptions include core size, core thickness, and

roundup values.

Re-optimization Features Off-Line Analysis

⦁ 3D stem images can be automatically saved to files for later

off-line “re-optimization” .

⦁ Off-line and on-line results are identical, allowing for

fine-tuning of settings without risking real wood.

⦁ Seamlessly integrates to our other optimizers.

User Friendly Interface

⦁ Microsoft Windows Professional multi-threaded, multi-tasking,

preemptive operating system, supporting multiple processors on an

Ethernet local area network (LAN).

⦁ Photorealistic high-resolution 3D graphics with configurable user

perspective.

Complete Suite of Reports

⦁ Provides complete information on system production and

performance, for accurate management decision-making.

Export Reports

⦁ Export reports to other formats like spreadsheets, databases, word

processors, and e-mail. Allows you to easily share information with

colleagues and re-purpose information for statistical purposes.

Reports on Demand

⦁ Print reports on demand or automatically to a preset schedule.

Information is available when you need it.

Create Your Own Custom Reports

⦁ Custom-design reports as needed for your mill’s individual needs.

Uses industry standard Business Objects reporting software and dBase

IV databases.