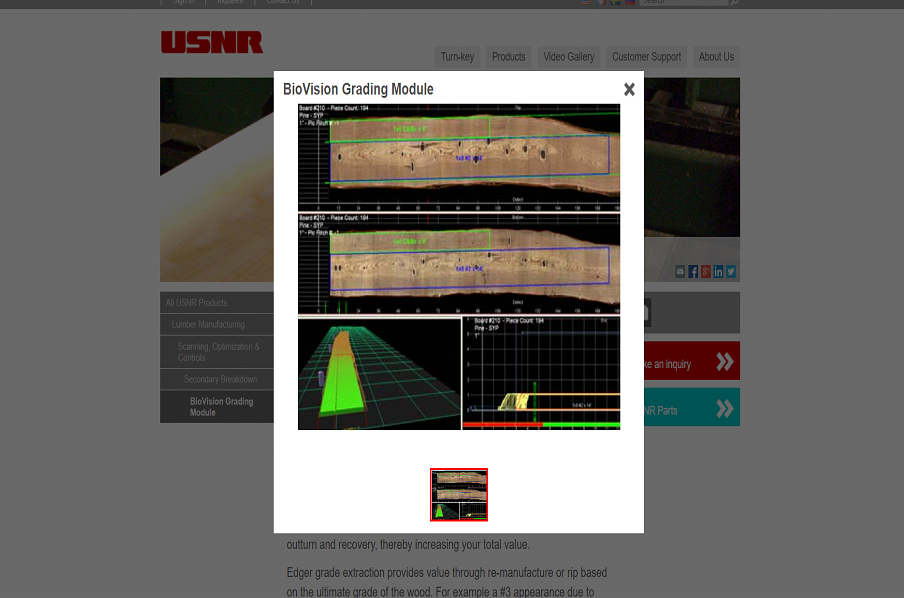

Now you can edge and trim for grade and value. Combining color vision technology with high density geometric scanning, the TrioVision Grading Module offers sawmills the highest value optimized decisions with grade and recovery performance. Designed for transverse edgers and trimmers, TrioVision makes value decisions driven by the accurate detection of biological and geometric defects using a combination of laser profile and visual defect scanning, combined with state-of-the-art optimization. The popularity of this technology is proven on several continents with a variety of species and wood markets worldwide.

Increased Grade, Recovery and Value:

⦁ Applying TrioVision technology in the sawmill increases your finished grade outturn and recovery, thereby

increasing your total value.

⦁ Edger grade extraction provides value through re-manufacture or rip based on the ultimate grade of the

wood. For example a #3 appearance due to knots can be edged to #3 wane with confidence, which maximizes

recovery. Likewise, a low grade 2x8 may be worth more as two 2x4's, one of them being high grade.

⦁ Trimmer grade extraction lets you cut-in-two allowing a short, high grade piece without trimloss.

'Candidate' trim stock meeting specified characteristics for wane and knots can be targeted and

sorted/routed differently for further unique action downstream. For example, by sorting for grade at the

trimmer, you can select more appropriate drying cycles for high or low grade products.

Investment Flexibility:

⦁ Our TrioVision-ready transverse scan frames will accommodate both geometric and vision scanning

capabilities, and offers the highest value return based on visual defect detection, rules based

classification and highly accurate geometric measurements.

⦁ As an option, you can choose to start with geometric-only scanning, and follow with visual scanning at a

later date. This requires changing out the laser profile sensors to sensors that feature both laser

profile and vision scanning. These sensors are an easy swap in the same scan frame.

What's Under the Hood?

⦁ The system utilizes our latest vision sensor, TrioStar900LV or LVG. The TrioPuma sensors contain high resolution digital color cameras and LED lighting to provide accurate images along with increased reliability.

⦁ The software incorporates algorithms from the proven Transverse High Grader (THG) automated grading system, used for recognition and classification of visual grade defects in the dry mill.

⦁ The TrioVision system combines this visual information with the geometric scan data generated by the transverse scanning system to determine a final solution.

⦁ Fitted with LVG sensors, the TrioVision system can also utilize GrainMap (grain angle) technology used for specific applications.

Major Elements of a New TrioVision System:

⦁ TrioVision frame ranging from 8' to 28' in length.

⦁ TrioStar900LV or LVG sensors with high resolution, digital color cameras.

⦁ High intensity LED lighting for defect scanning.

⦁ Computer bay.

⦁ Optimization software.

Defects Detected and Classified:

⦁ Thickness, width and length.

⦁ Wane and end-contour.

⦁ Warp (crook, bow).

⦁ Skip.

⦁ Knot size.

⦁ Knot quality.

⦁ Other visual characteristics.