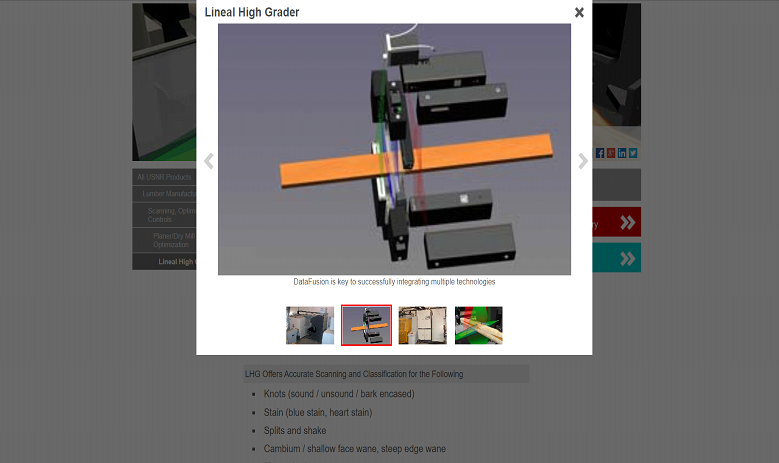

The Lineal High Grader (LHG) offers a complete and highly accurate automated grading solution. LHG scans each piece in a single pass employing several sensor technologies. It compares and verifies the data from these technologies to achieve a highly accurate decision. We call this approach DataFusion. Technologies include x-rays for density evaluation, lasers for geometric profile measurements, and 4-sided multi-channel vision to detect visual characteristics. The combination of these technologies allows classification and verification of lumber defects such as knots, stain, splits and shake, wane, rot, etc. and pith location down the entire length of the piece. The LHG also offers MSR/MEL strength classification, wane evaluation, and skip control with a high scan density in a very small footprint.

LHG Offers Accurate Scanning and Classification for the Following:

⦁ Knots (sound / unsound / bark encased).

⦁ Stain (blue stain, heart stain).

⦁ Splits and shake.

⦁ Cambium / shallow face wane, steep edge wane.

⦁ Planed bark as wane.

⦁ Decay (rot w/ voids, white spec, etc.).

⦁ Pith location down the entire length of the piece.

⦁ MSR/MEL strength evaluation.

Other Features:

⦁ High scan density: 0.2”.

⦁ Small footprint - 10’ in length.

⦁ True differential thickness & width measurements.

⦁ Wane equivalency, skip, warp, twist, crook, etc.

⦁ Can be close coupled to the planer.

⦁ Capable of operating at 3000+ feet/min. (915 m/min.).

⦁ Proprietary multi-channel, multi-spectral vision sensors.

⦁ See also our LHG ID Printer.

Modular Design Benefits:

⦁ The modular design of the LHG enables this unique grading optimizer to grow step-by-step to meet your

requirements or expand your mill's capabilities.

⦁ The LHG frame is designed to be compact yet accessible, and once installed it will receive additional

modules without structural modifications and without interruption to production.

⦁ The LHG scans the board and its grade solution is sprayed on the top of the board. The board is tracked

through the system using an ID that is printed on the bottom of the board as it exits the LHG.

Base Model (Geometric Scanning):

⦁ The base unit precisely determines all geometric features of a board including size, wane, skip, holes,

crook, bow and twist. This allows graders to focus on the visual defects longer, improving the quality of

their decision and greatly reducing grader fatigue.

⦁ Graders can agree with or downgrade the solution based on their visual data. They can enter lumber line and

non-lumber line grades and trims, plus choose an optional middle saw to aid in cut-in-two evaluation.

⦁ The optimizer determines the optimal grade and trim decision based on board profile data gathered by the

scanner, the grader's inputs, and product set-up values entered by mill personnel.

MSR/MEL Module:

⦁ Enhance the LHG's abilities by packaging X-Ray technology into the base unit. This feature allows the LHG

to predict strength and moisture content, enabling the mill to market high value MSR/MEL lumber.

E-Valuator Module:

⦁ E-Valuator is the enhanced MSR module. E-Valuator uses the non-contact deflection measurement, together with the density data gathered from X-Rays, to produce highly correlated Modulus of Elasticity (MOE) predictions.

⦁ E-Valuator can also use the 4-face multi-spectral scanners to add grain angle and moisture data collected down the entire length of the piece, to further enhance the stiffness prediction algorighms. This provides a greater yield compared with other single-technology systems available on the market.

⦁ This module has been operating since 2005, consistently outperforming the HCLT every month in bin yields.

Vision Module:

⦁ The vision module combines 4-face, multi-spectral vision information with density data from the X-Ray subsystem. Through DataFusion all the data is evaluated to extract the defect information specified per the mill's product parameters.

⦁ The vision module is based on years of proven, patented x-ray grading technology used in our other optimization products, a technology we pioneered with industry partners.

⦁ The vision module is available for all softwood species types.