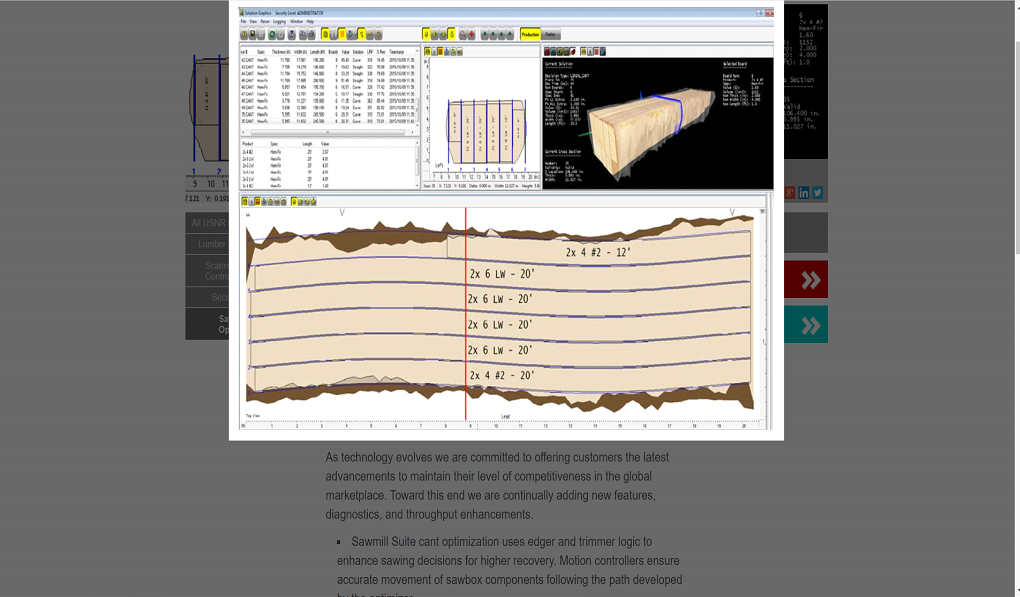

Today's optimization systems are tasked with providing increasingly complex features as mills work to compete in an ever-changing marketplace. The Rawmill Suite Cant Optimization system pioneered the curve sawing revolution, along with over 100 installations of the legendary McGehee curve sawing gang lines. It delivers unparalleled performance in lineal or transverse applications. Superior scan density provides more detailed information about each cant. This ensures highly accurate geometric measurements.

The Rawmill Suite software platform includes solutions for edging, trimming and curve sawing gang lines, paired with state-of-the-art scanning systems. Rawmill Suite is also available on our MyMill mobile optimization interface As technology evolves we are committed to offering customers the latest advancements to maintain their level of competitiveness in the global marketplace. Toward this end we are continually adding new features, diagnostics, and throughput enhancements.

⦁ Rawmill Suite cant optimization uses edger and trimmer logic to enhance sawing decisions for higher

recovery. Motion controllers ensure accurate movement of sawbox components following the path developed by the

optimizer.

⦁ Curve sawing optimization uses advanced fit logic to ensure the highest value sawing solution. The Rawmill

Suite cant optimization system will evaluate simplex ('C') curves as well as complex ('S') curves.

⦁ Rawmill Suite optimizer software allows bow in lumber from curved cants to be limited to prevent jam-ups in

downstream equipment.

⦁ Available in transverse or lineal configurations.

⦁ Our linear curve sawing cant optimizer systems offer high production speeds in a small footprint.

⦁ Rawmill Suite targets the most valuable solution that the gang saw is capable to produce.

⦁ Auto-calibrate function for fast tuning and easy routine maintenance.

⦁ Length accuracy to 1/4" (6.3mm) or better, no extra photocell required. Fewer components decreases

maintenance requirements and lowers cost of ownership.

⦁ Automatic failed sensor and debris detection. Immediate on-screen notification alerts the operator to a

problem, helps ensure maintenance issues are dealt with quickly.

⦁ Operates on the Microsoft Windows operating system to make better decisions through increased processing

power.

⦁ Intel DP support; increased processing speed.

Full skew optimization:

⦁ Of all the optimization configuration parameters, the skew set table has the biggest impact on

recovery.

⦁ Each skew in the skew set table determines the path the saw box will follow as it cuts the cant.

⦁ The optimizer will assess each skew in order, and utilize the skew and combination of boards that produces

the best value.

⦁ The full skew optimization procedure is designed to produce the most valuable solution based on log diet,

product and machine constraints, seasonal changes and product tuning.

⦁ Of all the optimization configuration parameters, the skew set table has the biggest impact on recovery.