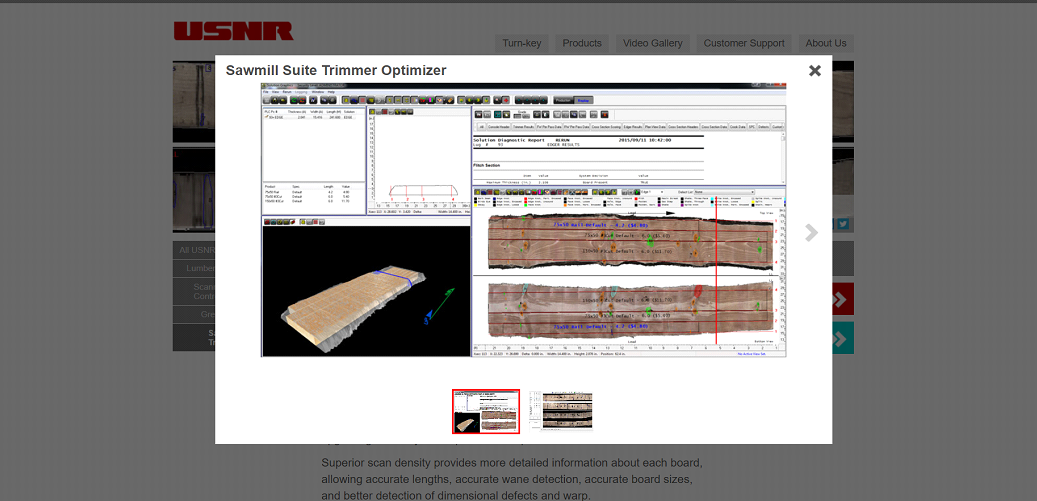

Today's optimization systems are tasked with providing increasingly complex features as mills work to compete in an ever-changing marketplace. The Sawmill Suite trimmer optimizer can provide accurate trim optimization that is crucial to maximizing mill profits. Sawmill Suite software includes solutions for edging, trimming and curve sawing gang lines, paired with state-of-the-art scanning systems. The Sawmill Suite Trimmer Optimizer is compatible with our BioVision green mill grading solution.

Reducing over/under trim can produce dramatic results. Relevant application-matched features, variable density sensors, reliability and intuitive user interface are direct results of the experience we've collected in hundreds of installations. The modular design of our optimizers allows future upgrading with very low impact on the operation of the sawmill. Superior scan density provides more detailed information about each board, allowing accurate lengths, accurate wane detection, accurate board sizes, and better detection of dimensional defects and warp.

We have integrated its optimization products with the latest scanning technology to take advantage of vision-based data collection and classification, offering even more valuable recovery from the raw material. Sawmill Suite is fully integrated with our BioVision systems, for automated grading in green mill environments.

This platform is also available on our MyMill mobile optimization interface.

Evolving technology:

⦁ As technology evolves we are committed to offering customers the latest advancements to maintain their level

of competitiveness in the global marketplace. Toward this end we are continually adding new features,

diagnostics, and throughput enhancements.

Latest version:

⦁ Operates on the Microsoft Windows operating system to make better decisions through increased processing power.

⦁ Enhanced bow logic gives control over warp processing.

⦁ Enhanced end defect qualification with the HDPV planview system.

⦁ Improved database performance with Microsoft SQL Server Express.

⦁ Advanced reporting features in a portable database format.

⦁ Reduced hardware requirement.

⦁ Expanded sensor capability for vision and other technologies.

⦁ Product based defect configuration.

⦁ Smart data fill eases repetitive manual data entry.

⦁ Auto spec automatically assigns a product specification to a piece, based on its dimensions; allows user to configure required dimensions, by order of importance, for each specification.

⦁ Electronic information transfer; board information transfer to quality assurance tool.

⦁ System status display.

⦁ Real-time variation reporting and troubleshooting; monitors product mix, tolerances and upstream machine accuracy.

⦁ Off-line simulation and test modes; recorded board image and grade defect information for tine-tuning results and solving setup problems, system diagnostics and evaluation.

Random width logic:

⦁ Independent edge evaluation.

⦁ Square edge detection allows saws to be configured to set in/out from the board's edge.

⦁ Random width pieces fail for "too thick" (if resaw is not available downstream).

⦁ Easy sensor calibration.

Defect tuning:

⦁ Highly dense full-board scanning with no gaps, both vertically and horizontally; maximizes dimensional measurement accuracy.

⦁ Auto-calibrate function for fast tuning and easy routine maintenance.

⦁ Length accuracy to 1/4" (6.3mm) or better, no extra photocell required. Fewer components decreases maintenance requirements and lowers cost of ownership.

⦁ Automatic failed sensor and debris detection. Immediate on-screen notification alerts the operator to a problem, helps ensure maintenance issues are dealt with quickly.

Automated grading capability:

⦁ Rawmill Suite Trimmer Optimizer easily processes geometric, visual and grain angle measurement (GrainMap) scan data, for fully automated defect recognition and grade classification.

⦁ Knot detection and classification.

⦁ Split/shake detection.

⦁ Defect grade by product.

New standards:

⦁ Operates on the Windows 7 operating system to make better decisions through increased processing power.

⦁ Percent wane setup; wane is expressed as a percentage at a threshold.

⦁ Intel DP support; increased processing speed.

⦁ Enhanced decision logic ensures maximum product recovery, weighted for optimum centering, maximized value.

⦁ Equivalence setup configuration.

⦁ System status display.

⦁ Auto spec automatically assigns a product specification to a piece, based on its dimensions; allows user to configure required dimensions, by order of importance, for each specification.

⦁ Accommodates up to 8 saws, 7 tailers, outside chip heads, collared or guided saws, stub arbor. Saws can be configured with a variation of fixed bank, mix of fixed and moving saws, etc.

⦁ Fixed width enhancement; processes dimension, boards, timbers, planks, decking, etc., both domestic and export.

⦁ Random width enhanced logic supports independent edge evaluation, enhanced value search, and more.

⦁ Employs full edger logic.

⦁ Smart data fill eases repetitive manual data entry.

⦁ Off-line simulation and test modes; recorded board image and grade defect information for fine-tuning results and solving setup problems, system diagnostics and evaluation.

⦁ Control of warp defects in trim solutions.

⦁ Planview defect depth calculation.

⦁ Enhanced bow evaluation.

⦁ Continuous board graphics.

⦁ Powerful reports package.

⦁ Standardized user interface.